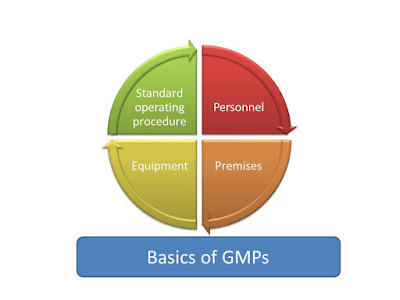

Every pharmaceutical manufacturer is responsible for establishing a GMP system in his manufacturing industry. In order to maintain an established framework of GMP system in theThe most essential requirements for maintaining good manufacturing practices in pharmaceutical industries is to have a strong system for

Personnel

Personnel is the most important component to have a good framework of GMP. It is the responsibility of the manufacturer to appoint a sufficient number of qualified personnel with the necessary qualification and practical experience. The manufacturer should have an organization chart with defined job description in which necessary qualifications and experiences should have already been defined. Specific duties and adequate authority should be specified clearly in the job description. There should not be any gaps or unexplained overlaps in the responsibility of the personnel involved in the application of GMPs.

It is also essential that the personnel receive induction as well as continuous training including all aspect of GMPs and instruction relevant to their needs.

Key personnel

- Head of Production

- Head of Quality Control

- Qualified Personnel

- He has to ensure that products are produced and stored as per the instructed SOPs.

- He has to approve the instruction relating to production and ensure its implementation.

- He has to ensure that the production records are assessed and signed by an approved individual before they are sent to the quality control department.

- He is responsible for the maintenance of his department, premises, and equipment.

- He has to ensure that appropriate validation is done.

- He is responsible for the individual induction and continuous training in his department.

Head of Quality control has following responsibility:-

- He has to approve specification, sampling instruction, test method and QC procedure.

- He has to approve/reject starting material, packaging material, intermediate material or bulk or finished product.

- He has to ensure that all necessary testing is carried out.

- He has to ensure that appropriate validation is carried out.

- He is responsible for the individual induction and continuous training in his department.

- He has to approve and monitor any contract analyst.

- He is responsible for the maintenance of his department, premises, and equipment.

- He has to evaluate the batch record

This is to be noted that above are the minimum requirement mentioned to maintain an established framework of GMP.

Qualified persons:

The qualified person is a specialized term that is utilized in Europea union pharmaceutical regulations (Directives 2001/83/EC for Medicinal products for human use). According to the regulation until and unless a qualified person releases a batch, the same cannot be released for sale.

In PICS, The qualified person is named as responsible person (RP) or authorized person (AP).

Premises

Premises refers to the specific arrangement of physical facilities. Premises include all elements in the building and building surrounding: the outside property, roadways, building design and construction, production flow, sanitary facilities and water/steam and pest control.

They should be designed, constructed and maintained in a manner to prevent the condition that may result in the contamination of the product. Essential components of the premises are described as below;

Outside Areas:

Ceiling, Walls, and Floors

Premises

Premises refers to the specific arrangement of physical facilities. Premises include all elements in the building and building surrounding: the outside property, roadways, building design and construction, production flow, sanitary facilities and water/steam and pest control.

They should be designed, constructed and maintained in a manner to prevent the condition that may result in the contamination of the product. Essential components of the premises are described as below;

Outside Areas:

- All outside areas of the premises should be free of debris that may be the source of insects, rodent infestation or cause for objectionable odor, smoke, dust or other contaminants.

- The facility should be designed light, constructed and maintained in good repair to prevent entrance and harboring of pest and entrance of environmental contaminants.

- The manufacturers should know his surrounding & working structure of the neighboring.

- All vehicles should be parked only in designated areas. Trucks, tempos or other commercial vehicles are allowed entries only if their tyres are cleaned and do not emit excessive smoke

Ceiling, Walls, and Floors

- Walls should be light colored floors sufficiently sloped for the liquid to drain to outlets.

- All grooves in the walls and floors are filled up.

- Roofs should be waterproofed to prevent ingress of leaking rain water.

- Ceiling and walls do not have peeling plasters.

- Walls are regularly cleaned to remove any dust.

Positive Air Pressure

- Positive air pressure should be maintained in packing, processing and drying areas to prevent the ingress of outside dust.

- Wherever practical air curtains are installed at the entrance of the high-risk areas.

- All exhaust fan should be in working condition. Exhaust fan opening should have self-closing shutters.

Ventilation and lighting

- Adequate ventilation should be provided to prevent heat buildup and to remove contaminated air.

- Adequate lighting is provided throughout the facility so that proper operation can be conducted.

Glass Policy

- All glass and brittle plastic shall be screened properly.

Toilets

- All toilets shall be regularly washed, flushed and cleaned with sanitizer. The toilets should have facilities for washing sanitizing and drying the hands.

Garbage

- All garbages should be disposed of in the municipal collection dumps. Laison should be kept with neighboring units to ensure that there is no cross contamination from their effluent or smoke emission.

Pest Control

- The pesticide is sprayed at regular interval on the advice of experts to prevent the breeding of pests. A Proper record should be kept of all pesticides.

- It is ensured that the finished, semi-finished or raw material is covered suitably to prevent any chemical contamination from the pesticide.

- Proper anti-rat measures should be adopted. Insect repelling lights are fitted at strategic spots.

- Doors should be closed fitted

Safety

- .Fire points are placed at different places and fire fighting devices like the fire extinguisher. They should be fitted at regular intervals with proper records of their filling. It should be ensured that fire bucket should be filled with sand and should be kept clear of any litter.

Process Equipment

Design & Construction

Maintainance

Standard operating procedures

Design & Construction

- The equipment should be suitably designed in such a way so that the equipment is easy to clean and to perform regular maintenance.

- It should be constructed in such a way so that the raw material, intermediate or finished product which comes in contact with the surface of the equipment should be contaminated.

- The equipment should be located suitably to solve its intended use.

- Installation qualification,Design qualification, equipment qualification and operational qualification should be perofrmed at the time of Installation. It shall be relavalidated at particular frequency.

- The design of the equipment shall be filed for future reference.

- Major equipment list should be maintained.

- Permanently installed lines shall be identified.

- Only food grade lubricants should be used. Measures should be taken to prevent the contamination from equipment lubricants.

Maintainance

- Periodic maintenance schedule shall be drawn.

- All periodic maintenance should be done as per the standard operating procedure. In determining the maintenance task guidance should be taken from the technical manual or similar kind of document.

- As per the checklist, preventive maintenance shall be performed.

- the preventive maintenance should be recorded for future reference.

Calibration

- Each equipment must be calibrated. Non calibrated equipment should not be used at any cost as the material produced with a calibrated equipment is always at question.

- The calibration should be done as per pre-decided standard operating procedure.

- Records of these equipment shall be maintained.

- Any deviation shall be recorded and investigated.

It is well known saying in the pharmaceutical industries is

"To write what you do and to do what is written."

These written instructions are known as standard operating procedures. There shall not be any activity in the industries without these standard operating procedures. These written procedures are the backbone of the pharmaceutical industries. All system shall be maintained by well-qualified personnel. It shall be prepared by the person who is either performing the activity or in consultation with the person performing the activity.It should be verified, and approved by higher authority.

These four essential component are the base of establishing the framework of the GMP system. If these are in perfect shape the pharmacuetical industry is than on the right tract to maintain the GMP System.

Readers are free to mail at quallpharmaconsultancy@gmail.com or anshuyadav.icgian@gmail.com.

AUTHOR

ANSHU YADAV

No comments:

Post a Comment